Energy Musings - October 14, 2024

A week ago, a ship departed New Bedford, MA with two blades from the Vineyard Wind project where a blade broke in mid-July. We explore this mystery and its meaning for offshore wind's future.

The Latest Vineyard Wind Mystery

A week ago, a giant transport ship, Rolldock Sun, was seen departing the Port of New Bedford, Massachusetts with two offshore wind turbine blades. According to the New Bedford Light newsletter, ship tracking services said the vessel was heading to the Port of Cherbourg, France. That is the location of a GE Vernova wind turbine manufacturing plant.

This development was a surprise. For the past year, ships have hauled blades into New Bedford, which were later sent offshore for installation. The mystery is why these blades are now heading in the opposite direction. What does it mean for Vineyard Wind 1’s $4 billion project following the failure of a turbine blade on July 13?

Vineyard Wind 1 blades heading back to France.

West Island Weather and New Bedford Light

Vineyard Wind 1 advertises itself as the nation’s first commercial-scale U.S. offshore wind farm. The 62-turbine, 800-megawatt (MW) project is located on federal lease OCS-A-0501, 15 miles south of Martha's Vineyard and Nantucket Island, and 35 miles from mainland Massachusetts. Its power is destined for Massachusetts utilities.

Blade debris landed all over this map.

Vineyard Wind selected GE Vernova’s Haliade-X 12+ megawatt (MW) turbines, capable of generating 13 MW of power. The turbines are manufactured at GE Vernova plants in Cherbourg, France, and Gaspé, Quebec, Canada. According to GE Vernova’s website:

“The Haliade-X platform was the industry’s first 12+ MW offshore wind turbine to operate. Furthermore, it is the platform with the longest operating history in the 12+MW segment, ensuring tangible experience operating the turbine in different conditions at different output levels. The Haliade-X offshore turbine features a range of power rating covering 12-14.7MW capacity, 220-meter rotor, a 107-meter blade, and digital capabilities. It has also received independent certification, making it a proven and bankable technology for customers seeking financing.”

The problem is the GE Vernova Haliade-X turbine blades have experienced three failures this year – two in England and one in Massachusetts. According to the company, each failure was caused by a different issue. The August UK Dogger Bank blade failure, the latest failure at that wind farm, was caused by a problem during commissioning, according to the company. The May Dogger Bank blade failed during installation. On the other hand, the July 13 blade failure at Vineyard Wind 1 was the result of a manufacturing problem.

The July Incident

At about 7 pm on the night of July 13, one of the AW-38 turbine blades bent over about 65 feet from its base. The photo below shows the damaged wind turbine. Pieces of the 360-foot-long blade fell into the ocean. The accident set off alarm bells at Vineyard Wind 1 which notified the Coast Guard. A 1,600-foot safety zone was set up around the turbine. However, Vineyard Wind delayed notifying Nantucket officials of the accident until Monday. The notice coincided with pieces of the blade washing up on Nantucket beaches forcing their closure – a significant problem for a tourist location dependent on the attraction of its beaches.

What was left of the blade on July 14.

Steve Heaslip/Cape Cod Times

Nantucket beaches were littered with pieces of the blade. (See photo below.) Subsequently, debris began appearing on the beaches of Martha’s Vineyard and the shores of Rhode Island and Cape Cod, Massachusetts. Eventually, blade pieces made it to Block Island and Montauk on the tip of Long Island.

Blade debris covers a Nantucket beach.

Recharge News

Nantucket residents and officials demanded answers about what had happened that Saturday night, how dangerous the blade debris was, and how often they might expect more such incidents. A Wednesday night town meeting, which included Vineyard Wind 1’s CEO Klaus Skoust Møller, provided no answers for residents. Møller told the assembled residents:

“This is a very serious situation and I am really truly sorry for the impact on your truly beautiful beaches here. Rest assured we will not just leave this as it is now. We will monitor it and we will keep the team here as long as is needed.”

Efforts to gain answers ended when Møller and several other Vineyard Wind officials suddenly left due to reports that the remainder of the blade had suffered an additional structural failure. The Vineyard Wind 1 officials jumped into their waiting helicopter and likely headed to the turbine for a look at the growing problem before heading home.

In response to the accident, on July 17 the Bureau of Safety and Environmental Enforcement (BSEE), a department within the Department of the Interior responsible for overseeing offshore energy operations, “issued a Suspension Order to Vineyard Wind to cease power production from all its wind turbines generators until it can be determined whether the blade failure affects any other VW turbines.” BSEE’s suspension order ended all new wind turbine generator construction activity.

Nine days later, BSEE restated and detailed actions allowed and disallowed under its suspension order.

“The order continues to prohibit Vineyard Wind 1 from generating electricity from any of the facilities or building any additional wind turbine generator towers, nacelles, or blades. This order also requires Vineyard Wind 1 to submit to BSEE an analysis of the risk to personnel and mitigation measures developed prior to personnel boarding any facility. Vineyard Wind 1 is not restricted from performing other activities besides those specifically directed for suspension or additional analysis. For example, Vineyard Wind 1 is still permitted to install inter-array cables and conduct surveys outside of the damaged turbine’s safety exclusion zone.”

The suspension order was further modified on August 13. Vineyard Wind 1 was allowed to install turbine towers and nacelles, but it was prohibited from installing blades or producing power. The project has now been unable to generate power for nearly three months. Not being able to install blades will delay the start-up of the wind farm. How long the suspension lasts will depend on the results of the investigations. It will impact the project’s economics, although the expenses may be recovered from GE Vernova.

The Blade Mystery

Sending two blades back to France raises questions. Has GE Vernova discovered additional manufacturing issues? Local media contacting Vineyard Wind after observing the departing heavy-lift ship received no information about why the blades were shipped to France. Is it possible that following re-inspections there are more blades with possible manufacturing defects? If so, what happens to the project’s timeline?

There is also uncertainty about the Bureau of Ocean Energy Management (BOEM) position regarding changes to its review and approval process, as well as incident-response protocols, for other offshore wind projects. There are also reports that BOEM is ordering Vineyard Wind 1 to complete an updated environmental harm assessment beyond what has already been done by GE Vernova.

Let’s see if we can make some sense of this blade mystery.

The Canadian plant was reportedly responsible for most of the first 150 wind turbine blades supplied. At the time of the July accident, Vineyard Wind 1 operated 10 turbines, and another 11 had been completed and were awaiting start-up. Those 21 turbines represent about a third of the ultimate 62-turbine wind farm. With three blades per turbine, the project has installed 63 blades out of the total of 186 blades. Reportedly, the Rolldock Sun had just arrived with four blades manufactured in France, but taking two back suggests a problem.

Eleven days after GE Vernova began its Root Cause Analysis of the blade failure, it concluded the problem was due to a manufacturing deviation at its Gaspé plant. The problem is related to the bonding of the material composing the blade. The company acknowledged the deviation should have been identified by its quality assurance process. That is not a good admission. It explains why GE Vernova management warned investors of the financial impact of the accident.

For GE Vernova, the three Haliade-X blade failures this year will have financial ramifications. The company only has two Haliade-X contracts. Both contracts suffered blade failures. Management says both contracts are in the red, but were they losing money before or only after the accidents? Losing money explains the company’s plan to shrink its offshore wind business. It plans to eliminate 900 employees, most likely from its Cherbourg operation. It will take a $300 million charge related to the contracts in the third quarter. It is working to complete its $3 billion backlog while continuing to blame cost inflation and supply chain issues for its financial problems.

Sending two blades back to France suggests GE Vernova must expand its initial blade failure investigation. How long might this investigation last? The possibility both plants have manufacturing issues is not good news for GE Vernova’s business. In April, the Cherbourg plant had an operational incident that damaged one of its two blade molds. The incident disrupted operations forcing the company to lay off its labor force temporarily which hurt its ability to secure additional business. It is probably partly responsible for the business losses.

On August 9, when Vineyard Wind 1 and GE Vernova published an Incident Response and Action Plan Overview of Blade Removal Operation, it set forth the steps it would be taking with the broken blade and to resume construction activity. Working with its salvage company, the plan was to remove the remainder of the broken blade, continue the debris clean-up, and inspect all its existing blades.

The Incident Response and Action Plan set out the standards to be met before blade installation and turbine start-up could resume. The plan stated:

“Re-review ultrasound photos: Re-process over 8,300 ultrasound testing (UT) records to determine whether bond requirements are satisfied. Any issues identified will be further inspected and corrective action taken as necessary.

“Internal Visual inspection: Advanced remote-controlled wheeled drones called “crawlers” are inserted into the manufactured blades to allow for current-state visual inspection of the blades. Crawlers are equipped with video cameras that can capture photos and videos for review by technicians to examine critical blade elements. Any anomalies identified will be flagged for further review prior to service.

“New ongoing real-time monitoring: GE Vernova is deploying a new algorithm, using existing fiber optic sensors already in the blade, and monitoring blade health designed to help avoid similar events. The algorithm will provide advanced warnings and/or automatic, safe turbine shutdown when triggered.

The Blade Debris Problem

Immediately after the July accident, the public worried about the danger of touching blade debris. Arcadis, a global engineering and environmental consultancy firm hired by GE Vernova, completed an initial ecological analysis of the blade debris. It concluded the debris is non-toxic and non-hazardous, comprised of "inert" materials — the same type used in things like recreational boats and textiles. GE Vernova acknowledged the blade had some pieces added on after manufacturing that contained small amounts of PFAS (forever) chemicals in the form of Teflon.

Not everyone was as sanguine about the risk of the debris as Arcadis. Nantucket Select Board member Malcolm MacNab, a physician, pointed out how irritable fiberglass used in the blade can be when people come into contact with it. Not only can fiberglass irritate a person’s skin, but it can also irritate their eyes if they come into contact with the material. Also, fiberglass can create respiratory issues if inhaled or swallowed.

Most of the blade debris has been collected, although some is likely still in the water or on the ocean floor. In the meantime, Vineyard Wind 1 must await completion of the GE Vernova and BSEE investigations before the operational suspension may be lifted. Reports are that the suspension may be extended for the rest of 2024. That suggests the blade failure investigations need more time and then BOEM will need time to weigh the results.

Given the growing number of offshore wind turbines, BOEM should consider the risk of blade failures in future offshore wind environmental reports. Of course, BOEM could elect to dismiss any consideration by claiming this was a rare, one-off event that is not worthy of more investigation or new rules. That is how they treat radar interference issues while they are dismissive of any possible connection between increased underwater noise from offshore wind farm construction and whale injuries or deaths.

Blade Failure Analysis

Onshore wind turbines have a history of blade failures, too. GE Vernova had three onshore wind turbine blade failures earlier this year at the Alfstedt-Ebersdorf wind farm in Germany. An independent investigation into the incident is still ongoing and likely won’t be finished until later this year, according to a spokesperson for that farm’s developer, Energiekontor. Will this investigation be considered along with the Haliade-X investigations in determining BOEM’s future policies? A blade is a blade, right?

It was suggested in an August posting on the website Citizens' Task Force on Wind Power – Maine that the Haliade-X blade was not properly tested for stress. Therefore, the person posting the information concluded that these blades are potentially at greater risk of failure.

As the offshore industry pushes for ever larger wind turbines to capture more energy and hopefully reduce the cost of offshore wind development projects, the question of whether these turbines are being properly tested and certified requires an answer. This criticism about inadequate testing before larger turbines were introduced and installed has been raised before. Engineers can model and test turbine designs on computers, but there is nothing better than sticking one out in the real world and seeing what Mother Nature does to it.

In 2022, the prototype Haliade-X 350-foot blade had to be tested before Vineyard Wind 1 would purchase the first 150 blades from GE Vernova’s Canadian plant. The blades were to be tested at a Massachusetts site. However, the site could only accommodate a blade 300 feet long. The solution was to cut off more than 50 feet of the blade. The cut-off end had weight added during the test to compensate for the missing blade section.

Testing the Haliade-X blade.

Here is where the engineers come in and extrapolate the test results for the 300-foot-long section to the 350-foot-long blade. The computer modeling proved the design so the blade was certified.

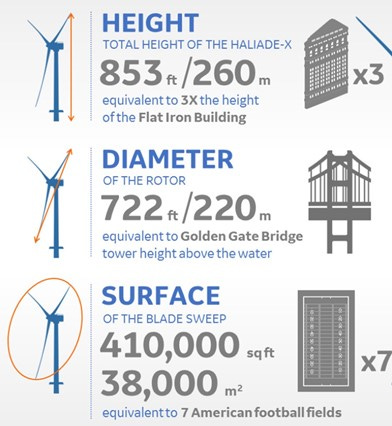

The turbine height is 853 feet tall with a blade diameter of 722 feet, based on 360-foot blades. The blades sweep an area of 410,00 square feet. The turbine’s nacelle (generator hub) sits roughly 500 feet above the water.

GE Vernova Haliade-X blade facts.

The challenge is that at the top of a sweep when the tip of the blade is 853 feet above the water, the wind speed is likely much greater than experienced by the tip of the blade at the bottom of the sweep. That means the turbine is constantly experiencing varying wind speeds and the blades are under different stress levels as they complete a full revolution. To overcome torsional fatigue from the varying wind speeds and stresses on the blade, they need increased reinforcement from carbon fiber, which adds significant expense. It was suggested that a blade should have been tested in a NASA wind tunnel before manufacturing the 150 blades. We do not know whether such an idea was considered or if it was even feasible.

In 1997, LM Glasfiber of Denmark issued a torsional fatigue warning for blades. It came after instances of stress cracks appeared on blades subjected to violent edgewise oscillation. The edgewise oscillation led to serious longitudinal cracks on the trailing edge of the blade close to its root. The root is the structure holding the outer part of the blade to the nacelle or hub.

The impact of torsional fatigue at the AW-38 turbine.

Before 1997, a blade oscillated so much that it hit the turbine tower causing the blade to break. The solution involved installing vibration detectors. The industry has been aware of the oscillation issue for more than 25 years. It is a problem with all wind turbine blades but increases with the length and weight of the blades.

Several years ago, Block Island Wind farm turbines displayed cracks causing Ørsted, its owner, to shut them down for inspection by their provider, GE Vernova. We were told that after inspection (and some repairs?) the turbines were declared to be fine and were restarted. Without access to company maintenance and repair records, we do not know what damage the turbines had and what remedies were used to fix them. These turbines are considerably smaller than those at Vineyard Wind 1 – 6 MW capacity versus 13 MW, with 490 feet versus 722 feet rotor diameter, and a hub height of 330 feet versus 500 feet. The smaller turbines and blades would not experience as wide a range of wind speed differences as the larger turbines. The Block Island Wind farm episode adds further mystery to the Vineyard Wind 1 blade failure.

The history of wind blade failures is instructive for modeling how many more incidents we could experience. The trade publication Wind Power Engineering & Development reported on a 2018 paper from a researcher at DTU Wind Energy, a department within DTU, a nearly 200-year-old university in Denmark. Denmark has been a leader in wind power and initiated the offshore wind industry. The paper reported that there are about 3,800 blade failures out of 700,000 operating blades which is a 0.5% failure rate. However, with wind turbines having three blades, the failure rate per turbine becomes 1.5%.

Interestingly, a review of more recent scientific studies on blade and wind turbine failures shows they all quoted the above data on wind blade failures. That may mean no one has compiled more recent data, or such analysis shows the failure rate is worse.

An interesting data point we uncovered in this search was what maintenance expenditures reveal about wind turbines. A 2022 paper ‒ Root Causes and Mechanisms of Failure of Wind Turbine Blades ‒ published in the journal Materials made the following points.

“However, the maintenance of wind turbines remains an important cost factor, influencing the energy price and competitiveness of renewable energy. For instance, onshore wind farm operators spent around USD 15 billion on operations and maintenance services in 2019, 57% of which was on unplanned repairs.”

The points were expanded upon by citing the aging of the wind turbine fleet. Older turbines demonstrate a higher maintenance and repair rate. Although the offshore wind turbine fleet is younger than the onshore fleet, operating conditions are worse – higher wind speeds, larger wind turbines creating greater stresses, and exposure to saltwater contamination. Furthermore, the frequency of maintenance is often lower because turbine locations result in higher costs to get repair workers and spare parts to offshore sites.

What does the 0.5% or 1.5% failure rate for blades and turbines imply for the East Coast offshore wind fleet? If President Joe Biden gets his pet environmental project of 30 gigawatts (GW) of offshore wind capacity installed by 2030, using a 13-megawatt (MW) wind turbine, it means 2,307 turbines. With three blades per turbine, we are talking about nearly 7,000 blades. At the historical failure rate, there could be 35 blade failures a year, or nearly three per month.

Because we are finding that wind farm turbines are becoming less productive over time and as they crowd each other, we may need to install closer to 3,000 turbines to reach the implied power generated by 30GW of capacity. The 30% increase in wind turbines and blades suggests 45 blade failures a year or almost four a month.

The Public’s View

If these failures occur, what will happen to the public’s view of offshore wind? In June, about a month before the Vineyard Wind 1 blade accident, the Barr Foundation conducted a poll of 400 residents of each of the three states ‒ Massachusetts, Connecticut, and Rhode Island ‒ about their views of developing offshore wind. The poll of the 400 Rhode Island residents showed 70% were in favor of developing offshore wind. Massachusetts (82%) and Connecticut (76%) respondents were more favorably disposed to offshore wind.

A poll of 800 likely voters in Rhode Island conducted from September 12-18 by MassINC Polling Group with funding from the Knight Election Hub showed a drop in support for offshore wind. Only 58% of respondents supported plans to bring more offshore wind to Rhode Island, compared with 34% who disapproved. How much of the lower support for offshore wind between the two polls is attributable to the July 13 blade failure?

Comparing polls is difficult when they are not conducted by the same organization. How the polling group was assembled and what their demographics are can make comparisons difficult. The wording of the questions can sway outcomes, too. However, a 12 percentage point difference suggests there has been an erosion in support for offshore wind.

We were dismayed at reading much of the media coverage of the blade failure. For example, when describing the worry of Nantucket residents about the toxicity of the blade debris, the fishing editor of The Providence Journal dismissed fears about fiberglass exposure by noting there are thousands of fiberglass boats in the coastal waters. Last time we checked, these fiberglass boats were not disintegrating and dropping their material into the water.

Conclusion

The Vineyard Wind 1 blade failure has upset the momentum of offshore wind. If the suspension order blocking installing blades and producing power lasts until the end of the year, the media will be forced to report that news repeatedly. Thus, the public will be reminded frequently of the economic and environmental costs of offshore accidents. The accident has undercut the offshore wind narrative that this is cheap energy and will be a boon for the economy.

A recent poll shows a decline in Rhode Island residents’ support for developing offshore wind is significant. Rhode Island is the state most exposed to environmental disasters and misinformation about blade failures. The data and recent history show these are not as rare an event as proponents want you to believe. The blade mystery has not been solved. What future surprises might it deliver?

Excellent expose on the debacle of another Vineyard Wind breakdown. It is strange how little national attention this Offshore Wind meltdown receives. Thank you Allen.